Yasir Jamal Bakare (Lead writer)

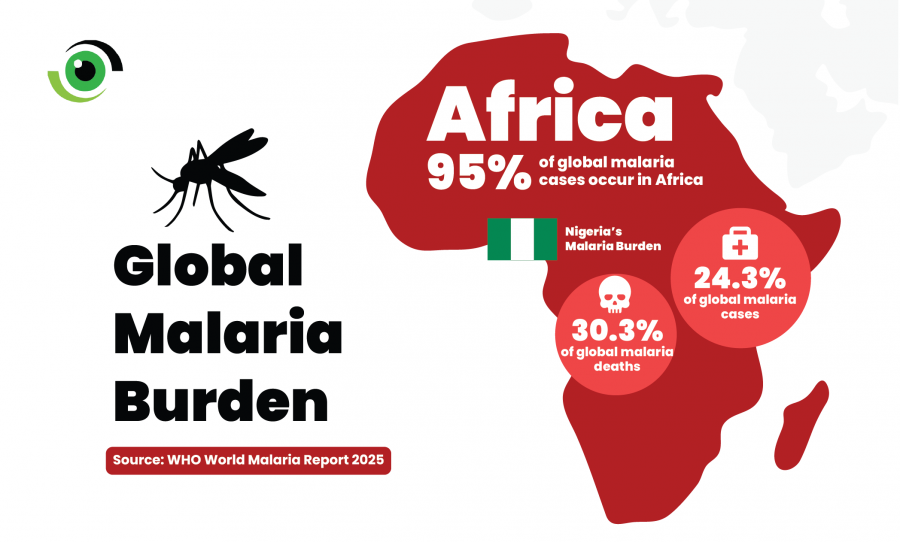

Nigeria accounts for roughly one in every four malaria cases worldwide, and nearly one in three malaria deaths. This places Nigeria at the centre of a disease that claims lives, drains household income, and strains health services. Yet for decades, one of the most effective prevention tools, long-lasting insecticidal nets (LLIN), has largely been manufactured outside the country, entrenching a reliance on external manufacturing and supply chains for such a key public health intervention.

In December 2025, Nigeria witnessed the groundbreaking of its first mosquito net manufacturing facility, designed to produce next-generation dual active-ingredient LLINs, including pyrethroid–chlorfenapyr nets. The plant is a joint venture between Vestergaard Sàrl and Harvestfield Industries, facilitated by the Presidential Initiative for Unlocking the Healthcare Value Chain (PVAC). This reflects a deliberate effort by Nigeria to align health security goals with industrial policy, recognising that reliance on external manufacturing was exposed during the COVID-19 pandemic, leaving Nigeria vulnerable to supply disruptions that undermine health security.

Why dual active-ingredient nets matter

Traditional insecticide-treated nets have saved millions of lives, but their effectiveness is increasingly threatened by insecticide resistance. Dual active-ingredient nets such as PermaNet® Dual combine two insecticides with different modes of action, improving protection in areas where pyrethroid resistance has reduced the impact of older nets.

Nigeria is positioning itself to become the first African country to manufacture dual active-ingredient long-lasting insecticidal nets at scale. By producing these nets locally, Nigeria strengthens its malaria response and signals readiness to adopt next-generation prevention tools as resistance grows. With climate pressures expanding mosquito habitats in some areas, sustained access to effective vector control will matter even more.

For many communities, especially in hard-to-reach rural areas, malaria remains a leading cause of illness, missed school days, lost income, and preventable deaths. Nigeria’s high share of global malaria mortality reflects long-standing gaps in reliable access to effective prevention. Local LLIN production should shorten lead times, reduce exposure to global supply shocks, and improve availability ahead of peak transmission periods. For households, that can mean fewer episodes of illness and lower out-of-pocket costs. For communities, it strengthens a proven first line of defence.

The facility is expected to begin production in April 2026, with annual capacity of up to 10 million nets, enough to cover roughly 30% of Nigeria’s LLIN demand. This scale has immediate public-health implications such as shorter procurement timelines, reduced exposure to global supply disruptions, and improved access to life-saving prevention tools.

Equally significant is the industrial dimension. The investment is projected to create about 600 skilled jobs, transfer advanced manufacturing technology, and strengthen Nigeria’s capacity to produce high-quality health commodities locally. In an era of shrinking donor budgets and increasingly fragile global supply chains, local manufacturing is no longer just an economic aspiration; it is a core pillar of health system resilience.

Dr Abdu Mukhtar, National Coordinator of PVAC, said the facility is important for both health security and industrial policy. “Every mosquito net produced here represents a Nigerian job, a Nigerian skill strengthened, and value created within our economy. This facility reaffirms our determination to ensure life-saving tools like PermaNet Dual are manufactured at scale, to global standards.” This approach aligns squarely with the objectives of PVAC to shift Nigeria from being primarily a consumer of imported health products to a producer and exporter of essential health commodities. The LLIN facility exemplifies how health outcomes and industrial development can be pursued together, rather than in isolation.

A regional hub in the making

While the immediate focus is domestic malaria control, the implications extend beyond Nigeria’s borders. At scale, the facility is designed to serve both local and international markets, positioning Nigeria as a West African manufacturing hub for insecticide-treated nets. This regional outlook reflects a broader continental push towards health sovereignty where African countries invest in their own production capabilities to meet shared public-health challenges.

Dr. Mukhtar also stressed that standards are non-negotiable. Quality assurance, proven mosquito-killing performance, and sustainability practices will determine whether local manufacturing delivers health impact, not just industrial output. While progress against malaria is multifaceted, including vaccines, treatment, and vector control, the World Health Organization and partners emphasise that insecticide-treated nets remain one of the most effective prevention tools. In addition to new vaccine introductions and broader surveillance strategies, expanding access to high-quality LLINs is vital for sustained reductions in transmission.

Building malaria prevention capacity at home

The establishment of this facility will not, on its own end malaria, but it represents an important shift towards addressing structural weaknesses in how prevention tools are produced and supplied. More importantly, it shows how policy leadership and private-sector expertise can align behind direct investment in local manufacturing, protecting lives while building domestic capacity.

For Nigeria, which carries the burden of a quarter of global malaria cases and a third of malaria deaths, prevention remains one of the most powerful tools available. Insecticide-treated nets are still central to cutting transmission and keeping families safe. Producing those tools locally, to global standards, strengthens supply security and marks a shift from dependency to capability.

As Nigeria takes this step, the message is clear. Malaria control is not only about distributing nets, but also about securing resilient, high-quality supply, and building the capacity to produce life-saving tools at home.